Using AI manufacturing in power plants can help companies save money on maintenance or create unique product designs. Almost half (49%) of people in the automotive and manufacturing industries think AI will be super important for manufacturing success in the next five years.

Manufacturers often deal with problems like machines breaking down out of the blue or products not turning out right. But by using AI and machine learning, they can make things better. These technologies help them work smarter, not harder. They can make operations run smoother, come up with new products faster, make products exactly how customers want them, and figure out smart money moves for the future. It’s like giving their business a digital makeover to keep up with the times.

But picking the right AI Tools For Manufacturing for a factory is like finding the perfect tool in a big toolbox—it’s tricky.

Why AI In Manufacturing is Important?

AI is becoming a big deal in manufacturing, with more and more companies jumping on board. In Europe, over half of manufacturers are already using AI, and Japan and the US aren’t far behind. Why the big fuss? Well, AI is great at fixing things and making stuff better. Take maintenance, for example. AI can help predict when machines might break down, so you can fix them before they do. And when it comes to quality, AI can spot problems faster than humans can.

Manufacturing is like a treasure trove of data, and AI loves data. There are so many things that can affect how stuff gets made, but it’s hard for humans to keep track of them all. That’s where AI comes in. It can crunch all that data and figure out what’s important, helping companies make better decisions.

Plus, the COVID-19 pandemic got manufacturers even more interested in AI. When lockdowns hit, companies had to find new ways to keep things running smoothly. AI turned out to be a lifesaver, helping them adapt to the chaos. So, it’s no wonder AI is becoming a big deal in manufacturing!

Also Read: AI Tools and Software For Finance

Where is AI Used In Manufacturing?

- Predictive maintenance: AI helps predict when machines might break down so they can be fixed before they cause problems, saving time and money.

- Quality control: AI can spot defects in products faster and more accurately than humans, ensuring that only high-quality items make it to the market.

- Process optimization: AI analyzes data from various stages of production to identify ways to improve efficiency and reduce waste, leading to cost savings.

- Supply chain management: AI helps optimize inventory levels, predict demand, and identify potential disruptions in the supply chain, ensuring smooth operations.

- Product customization: AI enables manufacturers to tailor products to individual customer preferences more efficiently, leading to greater customer satisfaction.

Also Read: AI Data Scraping Tools

Top 10 AI Tools For Manufacturing

1. TensorFlow

TensorFlow is an open-source machine learning framework developed by Google. It provides a comprehensive ecosystem of tools, libraries, and community resources for building and training various machine learning models, including deep neural networks. In manufacturing, TensorFlow is used for predictive maintenance, anomaly detection, process optimization, and quality control. For example, it can analyze sensor data from equipment to predict maintenance needs or detect defects in products on the production line.

How To Use:

- Install TensorFlow: Start by installing TensorFlow on your machine using pip or Anaconda.

- Data Preparation: Prepare your data for training your machine learning model. This involves data cleaning, preprocessing, and splitting into training and testing sets.

- Model Building: Define the architecture of your neural network using TensorFlow’s high-level APIs like Keras or its low-level APIs for more flexibility.

- Training: Train your model using the prepared data by specifying the loss function, optimizer, and other hyperparameters.

- Evaluation: Evaluate your model’s performance on the test set to assess its accuracy, precision, recall, etc.

- Deployment: Deploy your trained model in production environments using TensorFlow Serving, TensorFlow Lite, or TensorFlow.js, depending on your application’s requirements.

Features:

- Comprehensive machine learning framework

- Flexible architecture for building and training neural networks

- Scalable for both research and production use

- Extensive ecosystem with libraries, tools, and community support

- Support for various deployment options, including TensorFlow Serving and TensorFlow Lite

2. PyTorch

PyTorch is another popular open-source machine learning library, developed primarily by Facebook’s AI Research lab. It’s known for its dynamic computational graph, which makes it easier for researchers and developers to experiment with different model architectures and techniques. In manufacturing, PyTorch is used for similar purposes as TensorFlow, including predictive maintenance, quality control, and optimization tasks. Its flexibility and ease of use make it particularly suitable for research-oriented projects or prototyping new algorithms.

How To Use:

- Installation: Install PyTorch using pip or Anaconda following the instructions on the PyTorch website.

- Define Model Architecture: Design the architecture of your neural network using PyTorch’s nn module, specifying the layers, activation functions, and other components.

- Data Preparation: Prepare your data by loading it into PyTorch tensors and preprocessing if necessary.

- Training: Train your model by iterating over batches of data, computing the loss, and updating the model parameters using backpropagation and an optimizer.

- Evaluation: Evaluate your trained model on a separate validation set to assess its performance and fine-tune hyperparameters if needed.

- Deployment: Deploy your PyTorch model using tools like TorchScript for serving inference requests in production environments.

Features:

- Dynamic computational graph for flexible model development

- Pythonic API for ease of use and experimentation

- Strong support for GPU acceleration

- Tight integration with Python scientific computing libraries like NumPy and SciPy

- Active research community contributing to advancements in deep learning

Also Read: AI CRM Tools

3. IBM Watson

IBM Watson is a suite of AI tools and applications offered by IBM. It includes various cognitive computing services such as natural language processing (NLP), computer vision, speech recognition, and predictive analytics. In manufacturing, IBM Watson can be utilized for tasks like demand forecasting, supply chain optimization, customer sentiment analysis, and intelligent automation. For example, it can analyze customer feedback to identify trends and preferences, helping manufacturers tailor their products and services more effectively.

How To Use:

- Access IBM Cloud: Sign up for an IBM Cloud account and navigate to the Watson services dashboard.

- Choose Service: Select the Watson service relevant to your application, such as Watson Assistant for chatbots or Watson Studio for data analysis.

- Data Input: Provide your data to the selected Watson service, either through APIs, file uploads, or integration with other data sources.

- Configuration: Configure the Watson service settings, including training parameters, language models, and customizations.

- Training (if applicable): Train the Watson service using your data to improve its performance and accuracy, especially for services like Watson Natural Language Understanding or Watson Visual Recognition.

- Integration: Integrate the trained Watson service into your application or workflow using provided APIs and SDKs.

Features:

- Suite of AI services covering natural language processing, computer vision, and more

- Pre-trained models for common AI tasks with customization options

- Integration with IBM Cloud for scalability and reliability

- Developer-friendly APIs and SDKs for easy integration into applications

- Advanced features like sentiment analysis, entity recognition, and speech-to-text conversion

4. Microsoft Azure AI

Microsoft Azure AI is a cloud-based platform that provides a range of AI services and tools, including cognitive services, machine learning, and conversational AI. In manufacturing, Azure AI can be used for predictive maintenance, quality inspection, inventory management, and process optimization. Its scalable and integrated nature makes it suitable for deploying AI solutions across various manufacturing operations, from shop floor to supply chain management.

How To Use:

- Sign up for Azure: Create an account on the Azure portal and navigate to the AI services section.

- Choose Service: Select the Azure AI service that fits your needs, such as Azure Machine Learning, Azure Cognitive Services, or Azure Bot Service.

- Data Preparation: Prepare your data and upload it to Azure storage or connect it to your Azure workspace.

- Model Development: Develop your machine learning model using Azure Machine Learning Studio or Jupyter notebooks in Azure Machine Learning.

- Training: Train your model using Azure’s scalable compute resources and monitoring tools to track performance.

- Deployment: Deploy your trained model as a web service or container, making it accessible for inference requests from your applications.

Features:

- Cloud-based AI platform with a wide range of services

- Scalable infrastructure for training and deploying machine learning models

- Integration with other Azure services like Azure Storage and Azure DevOps

- Pre-built AI models and APIs for common tasks like vision, language, and decision-making

- Support for both Python and .NET development environments

5. Amazon SageMaker

Amazon SageMaker is a fully managed service by Amazon Web Services (AWS) that enables developers to build, train, and deploy machine learning models at scale. It provides a complete set of tools for data labeling, model training, and deployment, along with built-in algorithms and frameworks. In manufacturing, SageMaker can be used for predictive maintenance, anomaly detection, demand forecasting, and product recommendation systems. Its ease of use and scalability make it ideal for integrating AI into manufacturing workflows without requiring extensive expertise in machine learning.

How To Use:

- Sign up for AWS: Create an account on the AWS console and navigate to Amazon SageMaker.

- Data Preparation: Upload your training data to Amazon S3 or connect it to your SageMaker notebook instance.

- Model Development: Develop your machine learning model using SageMaker’s built-in algorithms, custom Docker containers, or Jupyter notebooks.

- Training: Train your model using SageMaker’s managed training infrastructure, specifying the instance type, number of instances, and other parameters.

- Evaluation: Evaluate your trained model’s performance using SageMaker’s built-in metrics and visualization tools.

- Deployment: Deploy your model to a SageMaker endpoint, enabling real-time or batch predictions via API calls.

Features:

- Fully managed service for building, training, and deploying machine learning models

- Built-in algorithms and frameworks for common machine learning tasks

- Scalable infrastructure with on-demand compute resources

- Integration with other AWS services like S3, Lambda, and API Gateway

- Extensible with custom Docker containers and Jupyter notebooks

6. Caffe

Caffe is a deep learning framework developed by Berkeley AI Research (BAIR). It’s known for its speed and modularity, particularly in computer vision applications. In manufacturing, Caffe can be used for tasks like defect detection, object recognition, and visual inspection of products on the production line. Its efficient implementation of convolutional neural networks (CNNs) makes it well-suited for real-time image processing and analysis, enhancing quality control and efficiency in manufacturing operations.

How To Use:

- Installation: Install Caffe by following the instructions provided in the official documentation or using precompiled binaries.

- Model Configuration: Define the architecture of your neural network model in a Caffe model definition file (prototxt), specifying layers, parameters, and connections.

- Data Preparation: Prepare your training and testing data by converting it into the required format compatible with Caffe, such as LMDB or HDF5.

- Training: Train your model using the caffe command-line interface or Python interface, specifying solver settings, learning rates, and other training parameters.

- Evaluation: Evaluate the performance of your trained model on validation or test data to assess accuracy, loss, and other metrics using Caffe’s evaluation tools.

- Deployment: Deploy your trained Caffe model for inference on new data, either by integrating it into a larger application or using Caffe’s deployment options like Caffe2 or OpenVINO.

Features:

- Fast and efficient deep learning framework, especially for computer vision

- Model Zoo with pre-trained models for various tasks

- Modular architecture for easy experimentation and customization

- Support for CPU and GPU acceleration

- Command-line interface for training and deployment

7. OpenCV

OpenCV is an open-source computer vision and machine learning software library. It provides a wide range of algorithms and tools for image processing, object detection, feature extraction, and more. In manufacturing, OpenCV is used for various applications such as defect detection, quality control, object tracking, and robotics. For example, it can analyze images from cameras installed on assembly lines to identify defects or monitor the movement of robotic arms in manufacturing environments.

How To Use:

- Installation: Install OpenCV library in your development environment using package managers like pip or through source code compilation.

- Image Acquisition: Capture or import images or video frames from cameras, files, or streams using OpenCV’s image acquisition functions.

- Preprocessing: Preprocess the input images as needed for your application, which may include resizing, filtering, color conversion, and noise reduction.

- Feature Extraction: Extract relevant features from the images using OpenCV’s feature detection and extraction algorithms like SIFT, SURF, or ORB.

- Object Detection/Recognition: Implement object detection or recognition algorithms using OpenCV’s pre-trained models or custom implementations, such as Haar cascades or deep learning-based methods.

- Integration: Integrate OpenCV into your application or system, either by incorporating it into your codebase directly or deploying it as a separate service.

Features:

- Open-source library for computer vision and image processing

- Rich collection of algorithms for feature detection, object recognition, and more

- Cross-platform support for Windows, Linux, macOS, Android, and iOS

- Integration with Python, C++, Java, and other programming languages

- Active community and extensive documentation with tutorials and examples

Also Read: AI Tools for E-commerce and Dropshipping

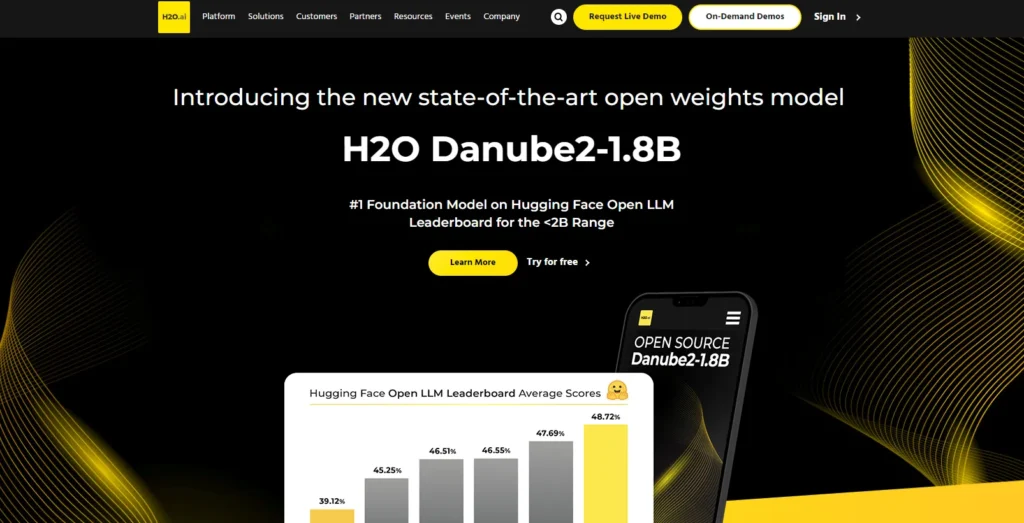

8. H2O.ai

H2O.ai is an open-source machine learning platform that provides tools for data analysis, predictive modeling, and machine learning algorithms. It offers various algorithms optimized for large-scale data processing and distributed computing environments. In manufacturing, H2O.ai can be used for predictive maintenance, process optimization, supply chain analytics, and demand forecasting. Its scalable and easy-to-use nature makes it suitable for building and deploying AI solutions across different manufacturing domains.

How To Use:

- Installation: Install the H2O.ai platform on your local machine or cloud environment by following the installation instructions provided in the documentation.

- Data Preparation: Prepare your dataset by importing it into H2O.ai’s data frames or data frames compatible with H2O.ai, ensuring data quality and formatting.

- Model Building: Build machine learning models using H2O.ai’s automated algorithms or custom models, specifying the target variable and features of interest.

- Training: Train your models on the prepared dataset using H2O.ai’s distributed computing capabilities, adjusting hyperparameters and model settings as necessary.

- Evaluation: Evaluate the performance of your trained models using H2O.ai’s model evaluation metrics and visualizations, comparing different models and tuning parameters.

- Deployment: Deploy your trained models for production use, either by exporting them as standalone Java artifacts or integrating them into existing applications using H2O.ai’s APIs.

Features:

- Open-source machine learning platform with distributed computing capabilities

- Automatic feature engineering and model selection with AutoML

- Scalable algorithms optimized for big data processing

- Integration with popular data science tools like R and Python

- Support for real-time scoring and model deployment

9. AutoML

Automated Machine Learning (AutoML) tools automate the process of model selection, hyperparameter tuning, and feature engineering, making machine learning accessible to non-experts. Examples include Google’s AutoML, H2O.ai’s Driverless AI, and others. In manufacturing, AutoML can be used to accelerate the development and deployment of AI solutions for predictive maintenance, quality control, demand forecasting, and other tasks. By automating repetitive tasks and optimizing model performance, AutoML tools enable manufacturers to leverage AI more effectively without requiring extensive data science expertise.

How To Use:

- Choose AutoML Tool: Select an AutoML tool or platform that best suits your needs and requirements, such as Google AutoML, H2O.ai’s Driverless AI, or AutoML services provided by cloud providers.

- Data Preparation: Prepare your dataset by cleaning, preprocessing, and splitting it into training and testing sets, ensuring data quality and compatibility with the chosen AutoML tool.

- Configuration: Configure the AutoML tool by specifying the target variable, evaluation metrics, time and resource constraints, and any custom settings or constraints.

- Model Training: Initiate the automated model training process, allowing the AutoML tool to explore various algorithms, feature engineering techniques, and hyperparameter settings.

- Evaluation: Evaluate the performance of the generated models on the validation or test dataset, comparing their accuracy, robustness, and other metrics.

- Deployment: Deploy the best-performing model from the AutoML pipeline into production, integrating it into your application or system for real-world use.

Features:

- Automated machine learning for building and optimizing models

- Simplified workflow with minimal manual intervention

- Support for various algorithms, hyperparameter tuning, and feature engineering

- Scalable infrastructure for handling large datasets and complex models

- Democratization of AI, making machine learning accessible to non-experts

10. Robot Operating System (ROS)

ROS is a flexible framework for writing robot software. It provides libraries and tools to help software developers create robot applications, from drivers to higher-level functionality. In manufacturing, ROS is used for controlling industrial robots, coordinating robotic operations, and integrating robots with other systems such as sensors and actuators. Its modular architecture and extensive library of pre-built components simplify the development and deployment of robotic systems in manufacturing environments, enabling tasks such as material handling, assembly, and inspection to be automated efficiently.

How To Use:

- Installation: Install ROS on your development environment or robot hardware platform by following the installation instructions provided in the ROS documentation.

- Package Management: Manage ROS packages containing libraries, tools, algorithms, and drivers for robot development and control, using tools like rospack and catkin.

- Node Configuration: Configure ROS nodes, which are modular units of robot software that communicate with each other through topics, services, and actions.

- Sensor Integration: Integrate sensors such as cameras, lidar, and IMUs into your ROS-based robot system, using ROS drivers and libraries for data acquisition and processing.

- Algorithm Implementation: Implement robot control algorithms, perception algorithms, and higher-level functionalities using ROS libraries and frameworks like ROS Navigation Stack or MoveIt.

- System Integration: Integrate ROS into your robot hardware platform, middleware, and other software components, ensuring compatibility, interoperability, and communication between different subsystems.

Features:

- Flexible framework for writing robot software

- Modular architecture with reusable components (nodes)

- Tools for sensor integration, perception, planning, and control

- Support for various robot platforms and hardware interfaces

- Active community contributing libraries, packages, and tutorials

Conclusion

In summary, the Manufacturing AI market is diverse, with tools tailored to specific manufacturing needs. Pure Play Startups focus on specialized solutions like predictive maintenance and quality control. Scale-ups offer a blend of innovation and reliability, catering to a wide range of functionalities. Big Tech Companies provide comprehensive toolsets covering predictive maintenance, quality control, manufacturing processes, and supply chain optimization. Each category plays a crucial role in advancing AI adoption and innovation in the manufacturing sector.